Optical Fiber Connector Ceramic Ferrule for Red Light Pen

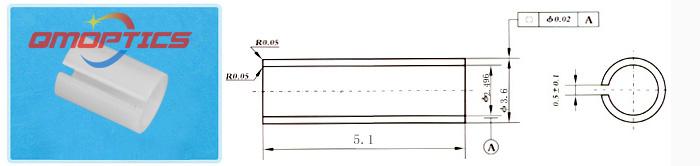

- Product Item : 30-003

- Category: Ceramic Ferrules

- Material: zirconia ceramic

- Hardness (HV): 1200MPa

- Operating Temperature: ≤1350℃

- Application: Red Light Pens

Optical Fiber Connector Ceramic Ferrule for Red Light Pen

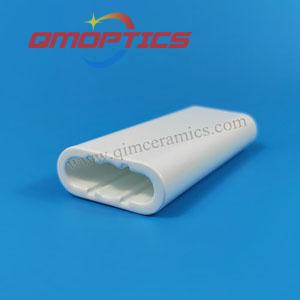

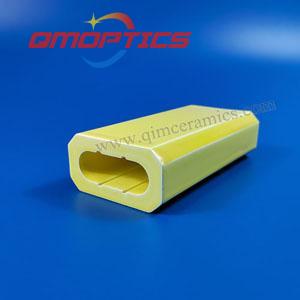

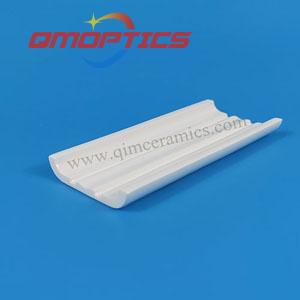

The zirconia ceramic ferrules are used for pens, such as letter red pen, small red pen, metal pen, red light pen etc. We provide all kinds of high precision zirconia ceramic core ferrules. The zirconia ferrules are available as split ferrules and solid ferrules.We also provide ferrules with special requirements such as tapered or chamfered lead in ends, and we supply custom ferrules for optical modules and devices. All zirconia ferrules are produced to meet your specific application requirements.

Product Features

• High Durability• Superior withdrawal force

• Split sleeves for adapters

• Solid sleeves for optical module

• Custom designs

Installation Method

Material Properties of Zirconia ceramic (ZrO2)

|

Description |

Unit |

Value |

|

Density |

g/cm3 |

6.05 |

|

Water Absorption |

% |

0 |

|

Thermal Expansion Coefficient |

10-6 /k |

10.5 |

|

Young's Modulus of Elasticity |

Gpa |

210 |

|

Poisson's Ratio |

/ |

0.3 |

|

Hardness (HV) |

MPa |

1200 |

|

Bending Strength (Room Temperature) |

MPa |

950 |

|

Bending Strength (700℃) |

MPa |

210 |

|

Compressive Strength (Room Temperature) |

MPa |

2000 |

|

Fracture Toughness |

Mpa.m1/2 |

10 |

|

Thermal Conductivity (Room Temperature) |

W/m.k |

2 |

|

Specific Resistivity (Room Temperature) |

Ω.mm2/m |

>1015 |

|

Operating Temperature |

℃ |

≤1350 |

|

Acid and alkali Corrosion Resistance |

/ |

Strong |

Other Dimensions In Stock

|

Type |

OD (mm) |

ID (mm) |

L (mm) |

|

LC Split ferrules |

1.8±0.02 |

1.245±0.002 |

4.9±0.1 |

|

Split ferrules |

3.2±0.02 |

2.496±0.002 |

7±0.1 |

|

Split ferrules |

3.2±0.02 |

2.496±0.002 |

10.1±0.1 |

|

SC Split ferrules |

3.2±0.02 |

2.493±0.002 |

11.4±0.1 |

|

Solid ferrules |

3.5±0.02 |

2.49±0.002 |

6.4±0.1 |

|

Split ferrules |

3.6±0.02 |

2.496±0.002 |

5.2±0.1 |

|

SMA Split ferrules |

4.1±0.02 |

3.16±0.005 |

14.5±0.1 |