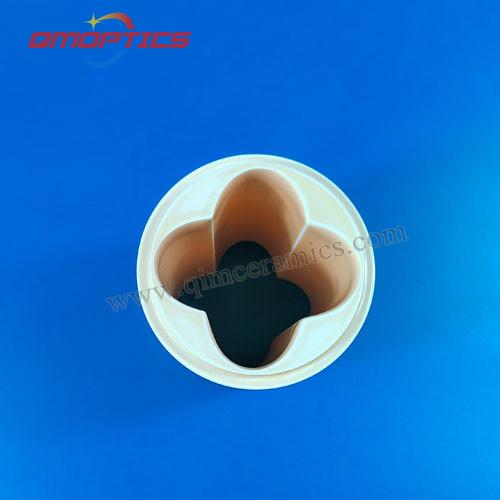

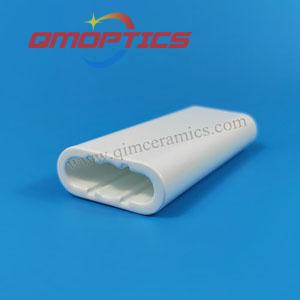

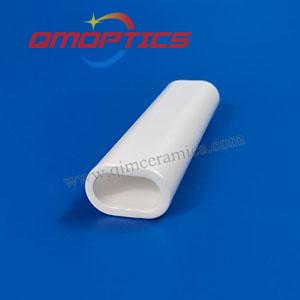

Yellow Glazed Laser Cavity Chamber For Solid-state Laser

- Product Item : 10-015

- Category: Ceramic Laser Reflectors

- Material: Alumina ceramic

- Purity: 99%

- Surface: UV cut-off yellow glaze

- Application: solid state lasers

Yellow Glazed Laser Cavity Chamber For Solid-state Laser

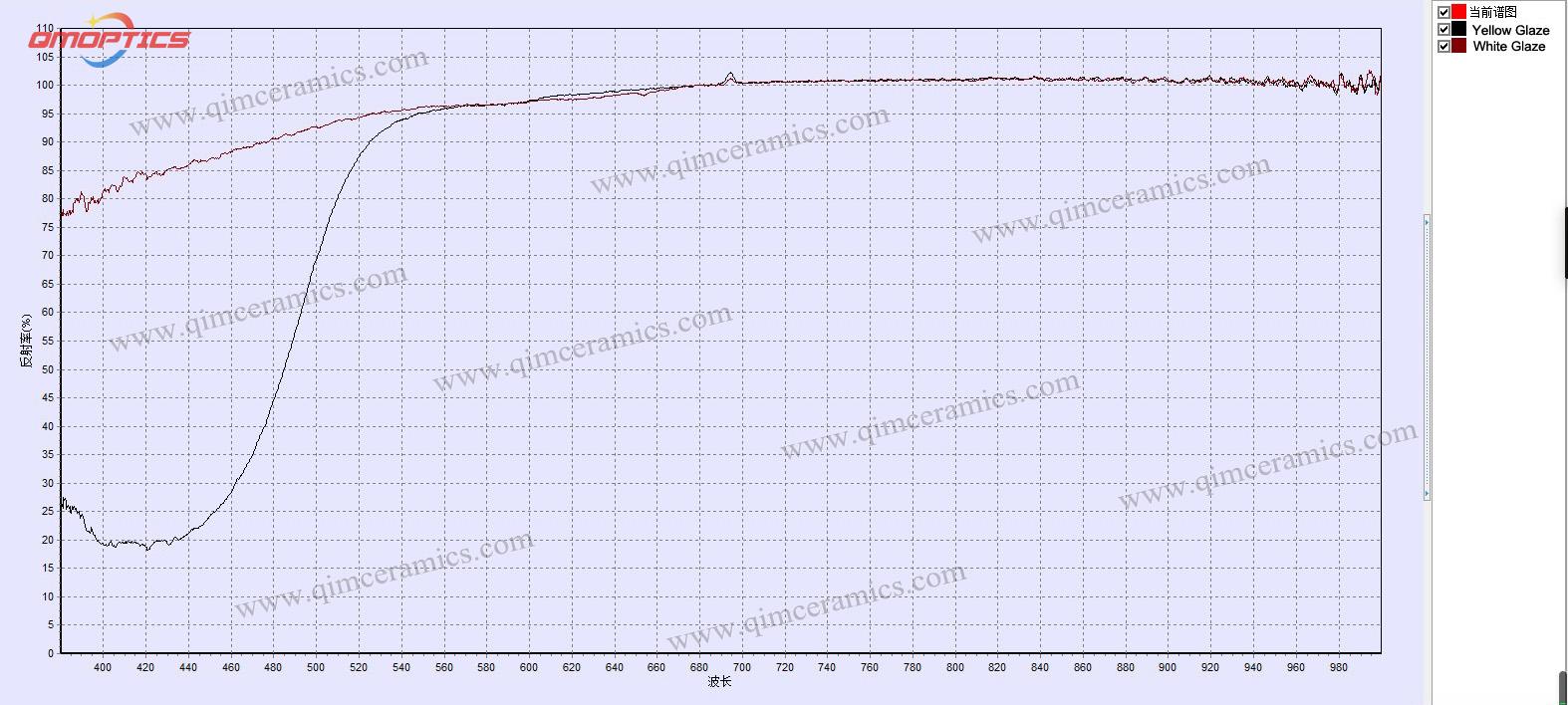

Plating yellow glaze on the outside of the Laser Cavity Chamber to make the ceramic focusing cavity in the main absorption band of the solid-state laser, exhibiting high reflectivity; At the same time, in the ineffective absorption band, it exhibits the function of reducing reflectivity. As a comparison, the diffuse reflection ceramic focusing cavity has high reflectivity in the non absorption band ultraviolet band of the laser crystal, but cannot effectively filter out ultraviolet light that produces harmful color centers to the laser crystal. Highly reflective and UV absorbing ceramic glazes can significantly improve the shortcomings of ordinary ceramic focusing cavities, with characteristics such as resistance to strong laser irradiation, high insulation, corrosion resistance, easy cleaning, and UV absorption.Main Physical Characteristics

Material

Alumina ceramic

Purity

99%

Color

Yellow

Bulk Density (fired)

3.1g/cm3

Porosity

22%

Surface Treatment

Non-glazed, Semi-glazed, Glazed, Yellow glazed

Bending Strength

170MPa

Thermal expansion coefficient

7.9×10-6/C (200-500℃)

9×10-6/C (200~1000℃)

Thermal shock resistance

No crack when temperature from 15-100℃ for 150 times

Product Features

• Easy to produce• Low production cost

• Large size

• Multi-functionality

• Mass production

• UV cut-off

Compared with white glaze, yellow glaze Ceramic Laser Reflectors has the function of absorbing ultraviolet radiation, which can improve the service life of crystals. The temperature of the crystal will not be too high, and ultraviolet radiation will be absorbed by the ceramic core. In the ultraviolet band, the reflectivity decreases by about 50% compared to the wavelength corresponding to white glaze.

Reflectivity Spectrum of Yellow Glazed Laser Cavity Chamber