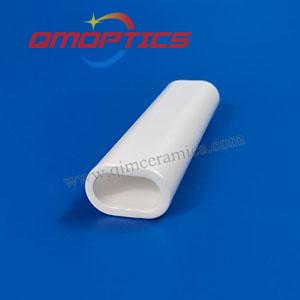

Yellow Glaze (GSY) for Ceramic Reflectors

- Product Item : 10-016

- Category: Ceramic Laser Reflectors

- Material: Alumina ceramic

- Purity: 99%

- Surface: Yellow glazed

- Minimum Order Quantity: Negotiable

Yellow Glaze (GSY) for Ceramic Reflectors

Ceramic Reflector is alumina-based ceramic which performs diffuse reflection. It boasts high strength, good thermal conductivity and excellent dimensional and electrical stability at all operating temperatures. A cost-effective alternative to metal-coated reflectors, ceramic reflectors are also resistant to chemical attack and, when sealed with glazes, benefit from an increased life span and reduced total cost of ownership.Compared with white glaze, yellow glaze Laser Cavity Chamber has the function of absorbing ultraviolet radiation, which can improve the service life of crystals. The temperature of the crystal will not be too high, and ultraviolet radiation will be absorbed by the ceramic core. In the ultraviolet band, the reflectivity decreases by about 50% compared to the wavelength corresponding to white glaze.

Main Physical Characteristics

Material

Alumina ceramic

Purity

99%

Color

Yellow

Bulk Density (fired)

3.1g/cm3

Porosity

22%

Surface Treatment

Non-glazed, Semi-glazed, Glazed, Yellow glazed

Bending Strength

170MPa

Thermal expansion coefficient

7.9×10-6/C (200-500℃)

9×10-6/C (200~1000℃)

Thermal shock resistance

No crack when temperature from 15-100℃ for 150 times

Product Features

• Resistant to strong laser irradiation• Low reflectivity on UV wavelength

• Longer life service of crystal rods

Main Applications

• Laser Welding Machine,• Laser Cutting Machine,

• Laser Marking Machine,

• Medical Laser System

Working Temperature

It is best not to keep the working temperature of glazed ceramic reflectors above 300℃ for a long time, otherwise crystallization may occur.The working temperature of non glazed ceramic reflectors can be 1200℃.

Reflectivity Spectrum of Yellow Glaze (GSY)