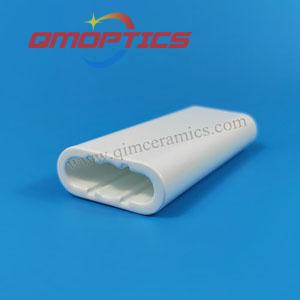

Solid-state Glazed Alumina Ceramic Laser Cavity

- Product Item : 10-018

- Category: Ceramic Laser Reflectors

- Material: Alumina ceramic

- Purity: 99%

- Surface: Full glazed

- Minimum Order Quantity: Negotiable

The Solid-state Glazed Alumina Ceramic Laser Cavity is prepared by doping 99% Al2O3, and the body is fired at an appropriate temperature to retain appropriate porosity and strength. The surface of the reflector adopts a fully glazed high reflectivity ceramic glaze process, which has the biggest advantage over gold-plated reflectors in terms of its long service life and diffuse reflection characteristics.

Main Physical Characteristics

Material

Alumina ceramic

Purity

99%

Color

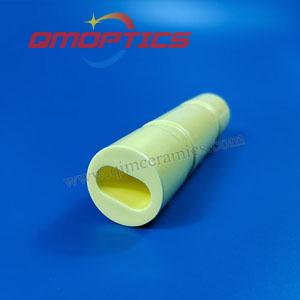

White / Yellow

Bulk Density (fired)

3.1g/cm3

Porosity

22%

Surface Treatment

Non-glazed, Semi-glazed, Glazed, Yellow glazed

Bending Strength

170MPa

Thermal expansion coefficient

7.9×10-6/C (200-500℃)

9×10-6/C (200~1000℃)

Thermal shock resistance

No crack when temperature from 15-100℃ for 150 times

Production Process

Raw material preparation → Forming → Repairing the blanks → Degreasing → Firing → Inspection → PackingProduct Features

• Easy to produce• Low production cost

• Large size

• Multi-functionality

• Mass production

Product Features

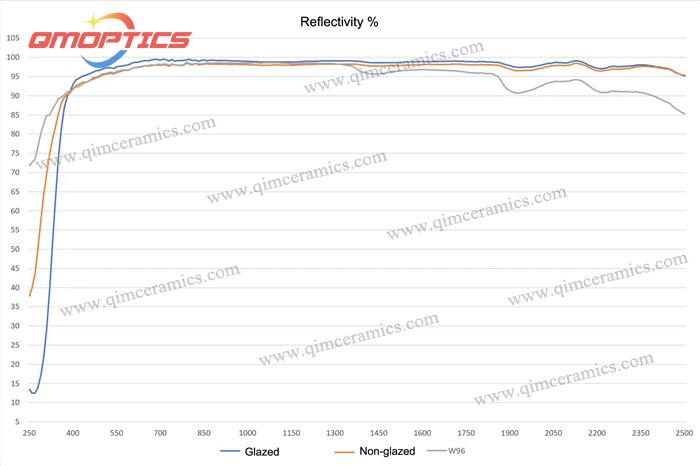

• Fully glazed surface for maximum reflectivity and easy cleaning• Reflectivity reaches 97% at wavelengths of 600-1000nm

• Reflectivity exceeding 95% within the wavelength range of 380-1100nm

• The green body has appropriate porosity and high strength characteristics

• Diffuse reflection for better working performance

Spectrum of Glazed Alumina Ceramic Laser Cavity

Main Applications

• Laser Welding Machine,• Laser Cutting Machine,

• Laser Marking Machine,

• Medical Laser System

Working Temperature

It is best not to keep the working temperature of glazed ceramic reflectors above 300℃ for a long time, otherwise crystallization may occur.The working temperature of non glazed ceramic reflectors can be 1200℃.

Precautions for Use

1. Ceramic reflectors must not be severely damaged by external forces during transportation, storage, and assembly, such as falling off to the ground, forcefully pressing into the pipe shell due to inappropriate size, etc;2. The semi glazed ceramic reflector must be sealed with the tube shell to prevent the ceramic reflector from inhaling a large amount of coolant, which may cause a decrease in power;

3. During assembly and maintenance, it is forbidden to scratch the ceramic reflective surface, which may cause a decrease in reflectivity, and the coolant may easily cause scaling on the ceramic surface during use;

4. When using short wavelength (such as 755nm) high-temperature systems, it is important to pay attention to the selection of cooling system piping and equipment materials to avoid contaminating the ceramic surface with free metal oxides.